iCue™ Dust Collector Monitoring Service

Remote Monitoring of your dust collection system

breadcrumb >> list

Donaldson iCue™ is a subscription-based dust collector monitoring service that can help identify disruptive & costly equipment performance issues.

iCue™ Remote System Monitoring

Operational Insights & Effecient Maintenance

Building on more than a century of filtration experience and the latest IoT technology, Donaldson’s iCue™ service is designed to remotely monitor a facility’s dust collection equipment and provide operational insights directly to end-users.

The information can help manufacturers reduce unplanned downtime, support efficient maintenance and operation, and automatically capture compliance data. The service will revolutionize the way organizations monitor, manage, and optimize their dust collection systems.

Features

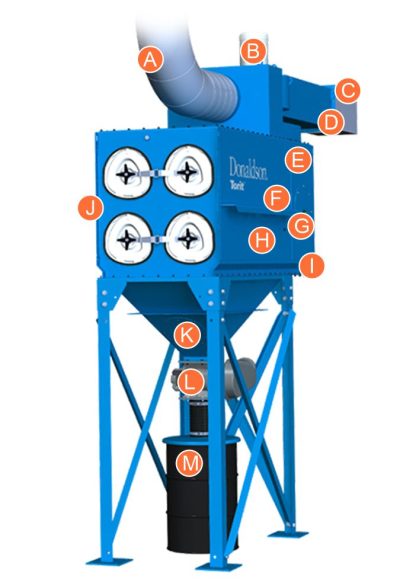

Airflow

STANDARD: This sensor monitors relative airflow, air volume, and velocity in the collector’s main inlet duct, measuring whether there is sufficient airflow to pull dust into the collector. Low-trending airflow could be the result of a plugged or expired filter and lead to potential EHS concerns.

Fan Energy and Power

OPTIONAL: Donaldson’s iCue connected filtration service can monitor power and energy use of the fan. It is ideal for customers whose dust collectors use a Variable Frequency Drive (VFD), that automatically adjusts fan speed to maintain optimal airflow.

Secondary Differential Pressure

OPTIONAL: Facilities with stringent air quality standards, or those returning air to the building, often have secondary filters, such as HEPA, included in their dust collection system. This sensor measures differential pressure (dP) across the HEPA media. Variations in dP across these filters can indicate they are damaged or need to be replaced.

Particulate Trend

OPTIONAL: This sensor monitors particulate trends in emissions. The particulate monitor provides alerts to prompt immediate attention before emissions limits are breached. It also provides accurate compliance data between tests, including documented evidence that particulate concentration is within defined regulatory limits.

Maintenance Hours of Service

STANDARD: The iCue service features a HOS feature that automatically detects when a machine is running, counts the hours of service, and alerts users when it’s time to perform regularly scheduled maintenance, based on their customized, preconfigured HOS thresholds.

Pulse Valve Health

STANDARD: Pulse Valve Health monitors pulse valve functionality and pulsing frequency on collectors with up to three manifolds to help detect compressed air problems or failed pulse valves which can affect filter life. If an issue arises with the pulse valves, the service sends an alert.

Gateway Temperature

STANDARD: This sensor promotes system longevity by tracking the temperature inside the wireless internet gateway device on the collector and providing alerts when optimal operating temperatures are exceeded.

Compressed Air Pressure

STANDARD: This sensor monitors changes in the compressed air pulse that cleans the filters. Data from this sensor can alert you to the need to restore normal cleaning functionality, increasing filter lifespan and generating potential savings on parts, labor, and unplanned downtime.

Internal Temperature and Humidity

OPTIONAL: This sensor detects both temperature and humidity from a single probe mounted inside the collector or a duct. Notifications are sent if the collector operates outside normal ranges, helping to avoid issues that can damage product or equipment.

Differential Pressure

STANDARD: This sensor monitors pressure drop as air passes through the filter media. Differential pressure (dP) is a valuable indicator of filter condition, and many regulatory agencies require dP reporting for air permits. By continuously monitoring dP, the iCue service can provide early alerts about filter issues: a sudden spike can mean a plugged air line or failed cleaning mechanism, while a rapid drop can mean a ruptured or damaged filter. You can also see when filters are approaching their maximum life, and plan filter changes around scheduled downtime.

Point Level (Hopper Plug)

OPTIONAL: This sensor, mounted on a rotating paddle inside the dust collector hopper, triggers an alert when the paddle can no longer rotate, which may indicate an obstruction. This sensor can also indicate a stopped rotary valve or overflowing bin. With early plugging detection, your team can troubleshoot the issue when it’s smaller, before filtration is interrupted.

Zero Speed / Rotary Air Lock

OPTIONAL: Typically used with collectors that have a rotary air lock. This sensor will detect when the rotary valve has stopped turning while the dust collector is running. Enabling users to take actions before the collector fills with particulate.

Bin / Drum Level

OPTIONAL: This sensor alerts users when their dust collector bins are nearly full, removing the guesswork about when to empty them, and preventing both filter damage and the mess that can result from dust overflow. This sensor is especially useful for operations whose bins fill frequently.

How iCue™ Can help

The iCue service monitors industrial dust and fume collectors – virtually eliminating the need to manually check readings. By continuously monitoring equipment operation and putting real-time performance data at your fingertips, the iCue service can help:

Support Efficient Maintenance and Operation

- Automatically monitor the status of all your dust collectors from a single web-based dashboard

- Identify potential issues before they create the need for larger, more time-intensive corrective action

Reduce Unplanned Downtime

- Monitor key parameters on the collector and proactively address issues

- Set and configure alerts so you receive notifications when pre-set thresholds are breached or your dust collector is operating outside the pre-set parameters

Manage and Track Regulatory Compliance Information

- Access real-time performance data to complete compliance reports

- Manage employee exposure risks by monitoring relative airflow through the dust collector

Manage Work In Challenging Environments

- Help manage staff exposure by reducing the need to access equipment and lower exposure to harsh weather, heights, ice, or debris

- Help manage staff exposure to potentially hazardous materials

How iCue™ Works

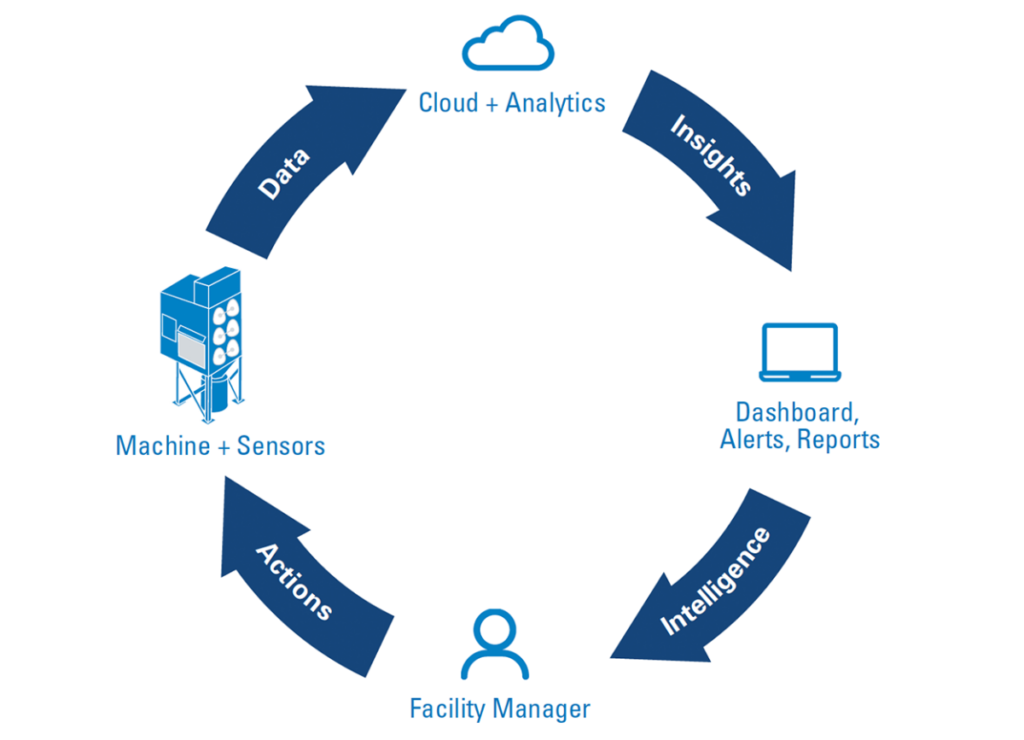

Donaldson’s iCue connected filtration service for dust collection provides a variety of sensor options that enable operators to track the parameters that are most important to their unique operations.

The iCue service works with nearly all major brands of dust and fume collectors, and includes a variety of sensor options so you can track the performance metrics that are most critical to your operation. Machine data from each connected device is collected and sent to Donaldson’s secure cloud, where it is transformed into actionable insights that are available on your dashboard. This web-based dashboard displays the status of all dust collection equipment across your operation, and lets you configure alarm levels and notifications.

- A Sensor Integrated Gateway monitors the dust collector’s core operation, tying into existing airlines and measuring several data points

- Aggregated data is sent to Donaldson’s secure cloud via a cellular connection, avoiding the need to link to a facility’s internal network

- An easy-to-use online dashboard enables visibility of all connected dust collectors from one or more facilities

- For more complex analysis, plotted data over various sensors and timeframes adds understanding of longer-term performance trends

- Immediate alerts notify responsible parties when issues arise that may require attention

- A weekly status report summarizes the overall status and performance of all connected dust collectors

Videos

Donaldson iCue™ Connected Filtration Service for Dust Collection

Donaldson’s iCue™ service is designed to remotely monitor a facility’s dust collection equipment and provide operational insights directly to end-users. The information can help manufacturers reduce unplanned downtime, support efficient maintenance and operation, and automatically capture compliance data.

Standard iCue™ Filtration Monitoring Capabilities

Explore all of the included connected filtration monitoring capabilities of the Donaldson iCue Filtration Service.

Optional iCue™ Filtration Monitoring Capabilities

Explore additional monitoring capabilities of the Donaldson iCue Service that can be added to support your unique operational needs.