Uni-Wash Wet Collection Booths & Enclosures

When source-capture is not possible

breadcrumb >> list

Wet Collection Booths & Enclosures

Wet Collection for Safe Collection of Metal Dust

A wet dust collector is required for the safe collection of combustible metal dust such as aluminum dust collection, titanium dust collection and magnesium dust collection.

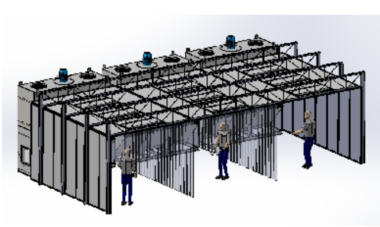

Wet Collection Booths When Source-Capture is not Possible

Wet dust collection booths can be utilized when source capture of an application is not efficient. Dust from your application will be contained within the booth. Air is continuously pulled into the Uni-Wash UEWC at the rear of the booth, filtered and exhausted into the ambient air of the facility.

NFPA 484 Compliance

Uni-Wash Wet Type Dust Collectors fulfill National Fire Protection Association (NFPA) Standard 484 for the capture of combustible metal dusts created in processes involving aluminum, magnesium, titanium, and zirconium (when purchased with the PRO package). If your process involves any or one of these materials, Uni-Wash Type Dust Collectors will greatly decrease the risk of fire and explosion in your facility – keeping your workers and your product clean, safe, and compliant.

Self-Contained with Little Water Requirements

Units are self-contained and require little or no water after filling. Installation and start-up are simple.

Applications

- Aluminum Sanding Dust Collection

- Aluminum Polishing Dust Collection

- Aluminum Grinding Dust Collection

- Titanium Processes Dust Collection

- Magnesium Sanding Dust Collection

- Magnesium Polishing Dust Collection

- Magnesium Grinding Dust Collection

- Zirconium Processes Dust Collection

- Pharmaceutical Dust Collection

- Food Processing Dust Collection

- Processes that do not suit media filtration

Wet Downdraft Bench & Enclosure Collector Models

UEWC-40 to UEWC-150

Features

- 4,000 – 15,000 CFM

- Can be used in multiple for large booth sizes

- Orifice / Impingement Patented Scrub Never Clogs

- Stainless Steel Scrub Components

- Integral High-Efficiency Fan Assemblies

- Solid Welded Construction

- No Filters to Replace

- Float Type Mechanical Water Level Control

- Various Power Options Available Including 575 Volts

Download brochure for detailed specifications and control options.

UC-40 to UC-300

Features

- Size: 6′ x 8′ x 8′ can increase by 2′ in each direction

- Galvanized Panels

- Flush-mounted lighting

- Heavy gauge structural support

- Flanges & Fasteners to mate with collectors

- Optional booth curtaining for the open side

- Optional crane slot

- Optional internal partitioning

- Recirculation from dust collector exhaust to assist containment

Download brochure for detailed specifications and control options.