Custom Pneumatic Conveying Systems:

Design, Efficiency & Safety Solutions

breadcrumb >> list

Optimize Material Handling with Custom Pneumatic Conveying Systems

Many facilities struggle with frequent blockages, excessive dust emissions, and inconsistent feed rates that slash production uptime. Custom pneumatic conveying systems solve these challenges through precision engineering and intelligent automation.

Pneumatic conveying uses air pressure to transport bulk materials through enclosed pipelines. These systems deliver clean, efficient, and safe material handling—especially for powders, granules, and bulk materials. Unlike off-the-shelf solutions, custom-built pneumatic conveyors are engineered specifically for your operational requirements, plant layout, and material characteristics.

Understanding Pneumatic Conveyors

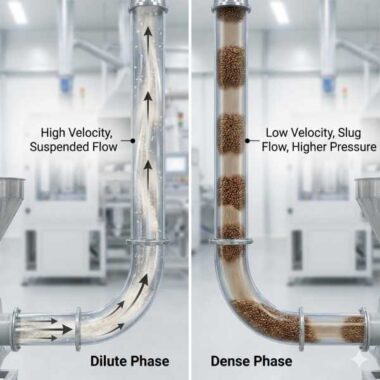

Dilute vs. Dense Phase Pneumatic Conveying

Dilute Phase Conveying

Materials are suspended in high-velocity airstreams at low concentrations (<15kg material per kg air). This method works best for non-abrasive, lightweight materials like flour and plastic pellets.

Dense Phase Conveying

Materials move at low velocity in slugs or plugs at higher concentrations (>30kg material per kg air). Ideal for abrasive, fragile, or heavy materials such as cereals and powdered carbon black.

Pressure vs. Vacuum Pneumatic Conveying Systems

Pressure

Air movers push materials from a single pickup point to one or multiple destinations using positive pressure. Best for long-distance conveying (up to 300+ meters), high-capacity operations, and applications requiring multiple discharge points.

Vacuum

Vacuum pumps pull materials from one or multiple pickup points to a single destination using negative pressure. Ideal for dust containment, multiple source collection, and applications requiring zero material leakage since any system leaks draw air in rather than releasing material.

Industry-Specific Applications

Pneumatic conveyors are not just limited to granular or powdered materials; they also play a crucial role in industries handling other forms of bulk materials.

Granular and Powdered Materials

Plastics Manufacturing

Chemical Processing

Pharmaceuticals

Food Processing

Move ingredients like flour, sugar, spices, and grains while maintaining sanitation standards and preventing cross-contamination.

Cement and Mining

Handle abrasive materials like cement, fly ash, and mineral powders in high-volume operations.

Bulk Materials Beyond Powders

Paper and Textiles

Pneumatic systems remove trim waste and fibers from production areas to collection sites, reducing manual handling.

Laundry Facilities

Industrial pneumatic conveying systems transport soiled linens from the receiving area to washers and clean items to sorting areas, improving hygiene while reducing labour costs.

Common Challenges Solved by Pneumatic Conveying Systems

Manufacturing facilities frequently encounter material handling problems that impact productivity and safety:

- Frequent blockages in standard systems cause costly downtime and require manual intervention

- Dust emissions create health hazards, contaminate products, and violate environmental regulations

- Material degradation from improper conveying damages product quality and increases waste

- Inconsistent feed rates disrupt downstream processes and reduce overall equipment effectiveness

- High energy costs from inefficient air movers and poorly designed pipeline routing

- Safety risks from handling hazardous or combustible materials in open systems

Custom pneumatic conveying design addresses these specific pain points by engineering solutions around your exact materials, facility constraints, and operational goals.

Why Custom Pneumatic Conveying Systems Outperform Standard Solutions

Precision-Engineered for Your Materials

Off-the-shelf systems rarely align with complex industrial operations. Custom solutions adapt every component to your specific needs.

Material Properties

- Abrasiveness: Wear-resistant materials like ceramic-lined pipes or hardened bends extend system life

- Moisture Content: Dehumidification or anti-clogging features maintain flowability

- Chemical Reactivity: Corrosion-resistant or inert contact surfaces protect against aggressive materials

- Particle Size & Shape: Optimized velocity, air-to-material ratios, and feeding mechanisms

Facility Layout Integration

- Space Constraints: Custom routing with vertical and horizontal transitions fits tight or complex footprints

- Seamless Integration: Direct connection to upstream feeders, silos, filters, and downstream processing lines

- Maintenance Access: Designed for easy inspection and modular expansion as your facility grows

Environmental and Safety Compliance

- Dust Control & Filtration: Fully enclosed systems minimize emissions and improve indoor air quality

- Explosion Protection: Systems meet NFPA standards with venting, suppression, and grounding for combustible materials

- Regulatory Compliance: Engineered to satisfy local and industry-specific regulations

Operational Cost Efficiency

- Energy Optimization: Right-sized air movers, smart routing, and efficient components cut power consumption by 15-30%

- Reduced Downtime: Systems designed for your materials prevent blockages and minimize wear

- Minimized Waste: Precision flow control prevents overfeeding, spillage, and losses

- Lower Total Cost of Ownership: Higher efficiency and reduced maintenance deliver long-term ROI

- Variable Frequency Drives (VFDs): Dynamically adjust motor speed to match real-time material demand, reducing energy consumption by 20-50% compared to fixed-speed systems while extending equipment life

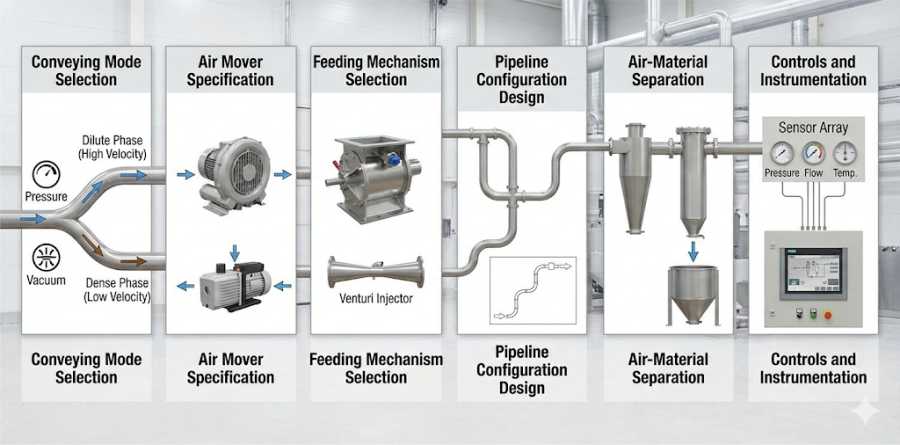

Key Design Elements of Engineered Pneumatic Conveying Systems

Every pneumatic conveying system combines specific design variables that determine performance, efficiency, and reliability.

Conveying Mode Selection

Air Mover

Specification

Pipeline Configuration Design

Feeding Mechanism Selection

Rotary valves, venturi injectors, or screw feeders control material entry. Precise feeding ensures consistent rates and prevents surges.

Air-Material Separation

Controls and Instrumentation

Pressure, flow, and temperature sensors integrate with automated control logic for stable operation, energy efficiency, and predictive maintenance.

Pneumatic Conveying Systems Comparison

| Feature | Dilute Phase | Dense Phase |

|---|---|---|

| Air Velocity | High (15–35 m/s) | Low (3–10 m/s) |

| Material Concentration | <15 kg/kg air | >30 kg/kg air |

| Best For | Lightweight, non-abrasive materials | Heavy, abrasive, fragile materials |

| Energy Use | Higher airflow requirements | Lower airflow, higher pressure |

| Material Degradation | Moderate to high | Minimal |

| System Complexity | Lower | Higher |

| Examples | Flour, plastic pellets, powdered sugar | Cement, carbon black, cereals, resins |

Selecting Your Custom Pneumatic Conveying Partner

Selecting the right vendor has a significant impact on both immediate performance and long-term reliability.

Experience and Proven Results

Partner with vendors experienced in your sector—plastics, chemicals, pharmaceuticals, food processing, or textiles. Capt-Air brings decades of expertise designing, installing, and maintaining turnkey pneumatic conveying solutions across diverse industries.

Request case studies demonstrating successful custom pneumatic conveying systems for materials and processes similar to yours.

Quality Assurance and System Reliability

Comprehensive Support and Service

- After-Sales Support: Training, spare parts availability, and technical assistance ensure long-term success

- Maintenance Programs: Regular service keeps systems running at peak efficiency and prevents unexpected downtime

- Total Cost of Ownership: Evaluate lifecycle costs—including maintenance, energy consumption, and downtime—not just an upfront price

Design and Engineering Capabilities

Your system should be engineered from the ground up to match your plant layout, materials, and process requirements. Look for vendors offering end-to-end project management—from concept through commissioning—including design, fabrication, installation, and system optimization.

Long-term Operational Efficiency

Selecting the right vendor is a strategic decision that affects not just the procurement and installation phases but the long-term operational efficiency of the pneumatic conveying system. Taking the time to evaluate potential vendors on these criteria will ensure that you partner with a company that can deliver a system tailored to your specific requirements and challenges.

FAQ

Frequently Asked Questions About Pneumatic Conveying Systems

What materials can pneumatic conveying systems handle?

Pneumatic systems transport powders, granules, pellets, fibers, trim waste, and bulk materials including plastics, chemicals, pharmaceuticals, food ingredients, cement, and textiles.

How do I choose between dilute phase and dense phase conveying?

Choose dilute phase for lightweight, non-abrasive materials requiring fast transport. Select dense phase for fragile, abrasive, or heavy materials needing gentle handling to prevent degradation.

What are typical energy costs for pneumatic conveying?

Energy costs vary by system size, conveying distance, and material characteristics. Custom-engineered systems typically reduce energy consumption by 15-30% compared to standard solutions through optimized air mover selection and pipeline design.

How long does custom pneumatic conveying system installation take?

Installation timelines range from 8-16 weeks depending on system complexity, facility integration requirements, and project scope. Your Capt-Air team provides detailed schedules during the design phase.

What maintenance do pneumatic conveying systems require?

Regular maintenance includes filter replacement, wear component inspection, air mover servicing, and control system checks. Preventive maintenance programs minimize downtime and extend system life.

Are pneumatic conveying systems safe for combustible dust materials?

Yes, when properly designed. Custom systems incorporate explosion protection features including grounding, bonding, venting, suppression systems, and compliance with the latest NFPA standards.

Invest in Custom Pneumatic Conveying Excellence

Custom-built pneumatic conveyors represent a strategic investment in operational efficiency, safety, and growth.

Tailored to your specific materials, layout, and production goals, these systems deliver:

- Improved process flow and energy efficiency

- Enhanced dust control and worker safety

- Full compliance with NFPA standards

- Future-proof design supporting facility expansion

Don’t settle for standard solutions that compromise your operation.

Have questions?

Contact Capt-Air now to explore how a custom pneumatic conveying system can optimize your material handling process.