Systèmes de convoyage pneumatique sur-mesure : Conception, efficacité et solutions de sécurité

breadcrumb >> list

Optimisez la manutention des produits grâce à des systèmes de transport pneumatique sur-mesure

De nombreuses installations sont confrontées à des blocages fréquents, des émissions de poussière excessives et des débits d'alimentation irréguliers qui réduisent le temps de production. Les systèmes de transport pneumatique sur-mesure permettent de résoudre ces problème grâce à une ingénierie de précision et une automatisation intelligente.

Le transport pneumatique utilise la pression d'air pour déplacer des matériaux en vrac à travers des conduits étanches. Ces systèmes offrent une manutention des matériaux propre, efficace et sécuritaire—particulièrement pour les poudres, les granules et les matériaux en vrac. Contrairement aux solutions standards, les convoyeurs pneumatiques sur-mesure sont conçus spécifiquement pour vos exigences opérationnelles, l'aménagement de votre usine et les caractéristiques de vos matériaux.

Comprendre les types de transport pneumatique : Concepts fondamentaux

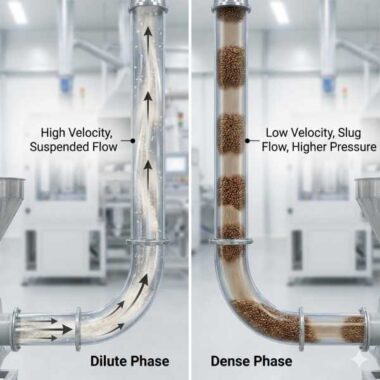

Transport pneumatique en phase diluée vs. phase dense

Transport en phase diluée

Les matériaux sont en suspension dans des flux d'air à haute vélocité à de faibles concentrations (<15 kg de matériau par kg d'air). Cette méthode convient particulièrement aux matériaux légers et non abrasifs comme la farine et les granules de plastique.

Transport en phase dense

Les matériaux se déplacent à basse vélocité en bouchons ou en vagues à des concentrations plus élevées (>30 kg de matériau par kg d'air). Cette méthode est idéale pour les matériaux abrasifs, fragiles ou lourds tels que les céréales et le noir de carbone en poudre.

Système de transport pneumatique en pression vs. sous vide

Pression

La pompe à vide aspire le produit d'un ou plusieurs points de collecte vers une seule destination en utilisant une pression négative. Idéal pour le confinement de la poussière, la collecte de sources multiples et les applications nécessitant zéro fuite de produit puisque toute fuite du système aspire l'air vers l'intérieur plutôt que de libérer du produit.

Sous vide

Les pompes à vide aspirent les matériaux à partir d’un ou de plusieurs points de captation vers une destination unique à l’aide d’une pression négative. Ce système est idéal pour le confinement des poussières, la collecte à partir de sources multiples et les applications nécessitant une absence totale de fuite de matériaux, puisque toute fuite du système entraîne une entrée d’air plutôt qu’une émission de produit.

Applications industrielles du transport pneumatique

Les convoyeurs pneumatiques ne se limitent pas aux matériaux granulaires ou pulvérulents ; ils jouent également un rôle essentiel dans les industries qui manipulent d’autres formes de matériaux en vrac.

Matériaux granulaires et pulvérulents

Fabrication de plastiques

Transformation chimique

Produits pharmaceutiques

Transformation alimentaire

Transformation alimentaire: Déplacez des ingrédients comme la farine, le sucre, les épices et les grains tout en maintenant les normes sanitaires et en prévenant la contamination croisée.

Ciment et extraction minière

Ciment et extraction minière: Manipulez des matériaux abrasifs comme le ciment, les cendres volantes et les poudres minérales dans des opérations à haut volume.

Matériaux en vrac au-delà des poudres

Papier et textiles

Les systèmes pneumatiques évacuent les rebuts de coupe et les fibres des zones de production vers des points de collecte, réduisant ainsi la manutention manuelle.

Buanderies

Les systèmes de transport pneumatique industriel transportent le linge souillé de la réception aux laveuses, et les articles propres vers les zones de tri—améliorant l'hygiène tout en réduisant les coûts de main-d'œuvre.

Défis courants résolus par les systèmes de transport pneumatique sur-mesure

Les usines manufacturières rencontrent fréquemment des problèmes de manutention de matériaux qui impactent la productivité et la sécurité :

- Blocages fréquents causent des temps d'arrêt coûteux et nécessitent une intervention manuelle

- Émissions de poussière créent des risques pour la santé, contaminent les produits et contreviennent aux réglementations environnementales

- Dégradation des matériaux causée par un transport inadéquat endommage la qualité des produits et augmente le gaspillage

- Débits d’alimentation irréguliers perturbent les processus en aval et réduisent l'efficacité globale des équipements

- Coûts énergétiques élevés dus à des ventilateurs inefficaces et à un réseau de conduits mal conçu

- Risques pour la sécurité Risques de sécurité liés à la manipulation de matériaux dangereux ou combustibles dans des systèmes ouverts

La conception de systèmes de transport pneumatique sur-mesure aborde ces points problématiques en offrant des solutions adaptées à vos produits, vos contraintes d'installation et vos objectifs opérationnels.

Pourquoi les systèmes de transport pneumatique sur-mesure surpassent les solutions standards

Conçus pour vos produits

Les systèmes standards répondent rarement aux applications industrielles complexes. Les solutions sur-mesure adaptent chaque composante à vos besoins spécifiques.

Propriétés des matériaux :

- Abrasivité : Matériaux résistants à l'usure comme les tuyaux revêtus de céramique ou les coudes durcis prolongent la durée de vie du système

- Teneur en humidité : Déshumidification ou caractéristiques anti-colmatage maintiennent la fluidité

- Réactivité chimique : Réactivité chimique: Surfaces de contact résistantes à la corrosion ou inertes protègent contre les matériaux réactifs

- Taille et forme des particules : Vitesse de convoyage, ratios air-matériau et mécanismes d'alimentation optimisés

Intégration dans votre espace :

- Contraintes d’espace : Réseau de conduits personnalisé qui s'adaptent aux environnements encombrés et complexes

- Intégration harmonieuse : Connexion directe aux équipements en amonts et en avals

- Accès pourl'entretien : Conçu pour faciliter l’inspection et l’extension modulaire à mesure que votre installation évolue

Conformité en matière de santé et sécurité au travail et d'environnement :

- Contrôle de la poussière et filtration : Les systèmes respectent les normes NFPA grâce à des dispositifs de décompression, de suppression et de mise à la terre pour les matériaux combustibles

- Protection contre les explosions : Les systèmes respectent les normes NFPA grâce à des dispositifs de décompression, de suppression et de mise à la terre pour les matériaux combustibles

- Conformité réglementaire : Conçus pour satisfaire les réglementations locales et spécifiques à chaque industrie

Operational Cost Efficiency

- Optimisation énergétique :Ventilateurs dimensionnés adéquatement, réseaux optimisés et composantes efficaces réduisent la consommation d'énergie de 15 à 30%

- Réduction des temps d’arrêt : Systèmes conçus pour vos produits préviennent les blocages et minimisent l'usure

- Réduction des pertes : Contrôle de débit prévient la suralimentation, les déversements et les pertes

- Coût total de possession réduit : Efficacité supérieure et entretien réduit offrent un retour sur investissement à long terme

- Variateurs de fréquence (VFD) : Ajustent dynamiquement la vitesse des moteurs pour correspondre à la demande en temps réel, réduisant la consommation d'énergie de 20-50 % comparativement aux systèmes à vitesse fixe tout en prolongeant la durée de vie de l'équipement

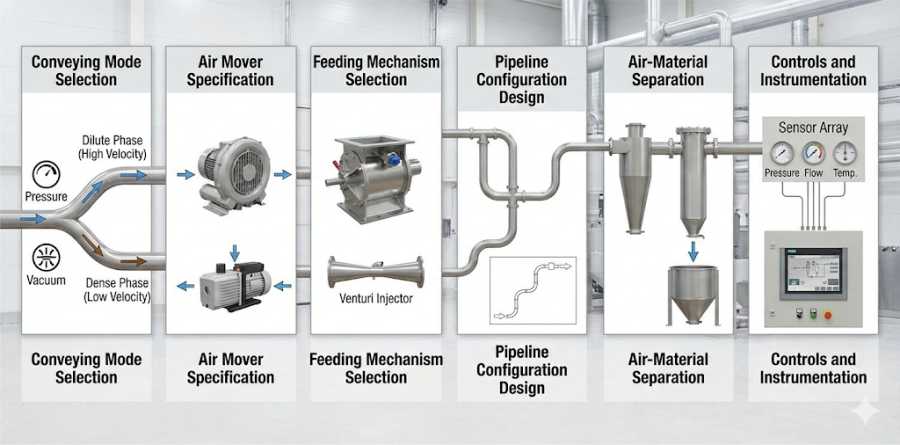

Éléments de conception clés des systèmes de transport pneumatique sur-mesure

Chaque système de transport pneumatique combine des spécificités de conception qui déterminent la performance, l'efficacité et la fiabilité.

Choix du mécanisme d'alimentation

Spécification du ventilateur

Conception du réseau de conduits"

Choix du mécanisme d'alimentation

Les vannes rotatives, les injecteurs venturi ou les convoyeurs à vis d'alimentation contrôlent l'entrée des matériaux. Une alimentation précise assure des débits constants et prévient les suralimentations.

Receveur

pneumatique

Commandes et instrumentation

Les capteurs de pression, de débit et de température s'intègrent avec la logique de contrôle automatisée pour une opération stable, une efficacité énergétique et un maintenance prédictive.

Comparaison des systèmes de transport pneumatique

| Caractéristique | Phase diluée | Phase dense |

|---|---|---|

| Vitesse de l’air | Élevée (15–35 m/s) | Faible (3–10 m/s) |

| Concentration de matériau | < 15 kg/kg d’air | > 30 kg/kg d’air |

| Idéal pour | Matériaux légers et non abrasifs | Matériaux lourds, abrasifs ou fragiles |

| Consommation d’énergie | Exigences élevées en débit d’air | Débit d’air plus faible, pression plus élevée |

| Dégradation des matériaux | Modérée à élevée | Minimale |

| Complexité du système | Plus faible | Plus élevée |

| Exemples | Farine, granules de plastique, sucre en poudre | Ciment, noir de carbone, céréales, résines |

Choisir votre partenaire en transport pneumatique sur-mesure

Le choix du bon fournisseur impacte à la fois la performance immédiate et la fiabilité à long terme.

Expérience et résultats éprouvés

Associez-vous avec des fournisseurs expérimentés dans votre secteur—plastiques, chimique, pharmaceutique, transformation alimentaire ou textiles. Capt-Air possède des décennies d'expertise dans la conception, l'installation et la maintenance de solutions de transport pneumatique clés en main dans divers secteurs industriels.

Demandez des études de cas démontrant des systèmes de transport pneumatique sur-mesure réussis pour des matériaux et des processus similaires aux vôtres.

Assurance qualité et fiabilité des systèmes

Support et service complets

- Support après-vente : Formation, disponibilité des pièces de rechange et assistance technique assurent le succès à long terme

- Programmes d'entretien : Un service régulier maintient les systèmes à leur efficacité maximale et prévient les temps d'arrêt imprévus

- Coût total de possession : Évaluez les coûts du cycle de vie—incluant l'entretien, la consommation d'énergie et les temps d'arrêt—pas seulement le prix initial

Capacités de conception et d’ingénierie

Votre système devrait être conçu de A à Z pour correspondre à l'aménagement de votre usine, vos matériaux et vos exigences de processus. Recherchez des fournisseurs offrant une gestion de projet de bout en bout—du concept à la mise en service—incluant la conception, la fabrication, l'installation et l'optimisation du système.

Efficacité opérationnelle à long terme

Le choix du bon fournisseur est une décision stratégique qui influence non seulement les phases d’approvisionnement et d’installation, mais aussi l’efficacité opérationnelle à long terme du système de transport pneumatique. Prendre le temps d’évaluer les fournisseurs potentiels selon ces critères vous permettra de vous associer à une entreprise capable de livrer un système adapté à vos exigences et à vos défis spécifiques.

FAQ

Questions fréquemment posées sur les systèmes de transport pneumatique

Quels matériaux les systèmes de transport pneumatique peuvent-ils manipuler ?

Les systèmes pneumatiques transportent les poudres, granules, fibres, déchets de coupe papier et matériaux en vrac incluant les plastiques, produits chimiques, pharmaceutiques, ingrédients alimentaires, ciment et textiles.

Comment choisir entre le transport en phase diluée et en phase dense ?

Choisissez la phase diluée pour les matériaux légers et non abrasifs nécessitant un transport rapide. Optez pour la phase dense pour les matériaux fragiles, abrasifs ou lourds nécessitant une manutention en douceur afin de prévenir la dégradation.

Quels sont les coûts énergétiques typiques pour transport pneumatique ?

Les coûts énergétiques varient selon la taille du système, la distance de transport et les caractéristiques des matériaux. Les systèmes conçus sur-mesure réduisent généralement la consommation d'énergie de 15-30 % comparativement aux solutions standards grâce à une sélection de ventilateur et un réseau de conduits optimisés.

Combien de temps prend l'installation d'un système de transport pneumatique sur-mesure ?

Les échéanciers d'installation varient de 8 à 16 semaines selon la complexité du système, les exigences d'intégration de l'installation et l'envergure du projet. Votre équipe Capt-Air fournit un échéancier détaillé durant la phase de conception.

Quel entretien les systèmes de transport pneumatique nécessitent-ils ?

L'entretien régulier inclut le remplacement des filtres, l'inspection des composantes d'usure, l'entretien des ventilateurs et les vérifications du système de contrôle. Les programmes d'entretien préventif minimisent les temps d'arrêt et prolongent la durée de vie du système.

Les systèmes de transport pneumatique sont-ils sécuritaires pour les matériaux de poussière combustible ?

Oui, lorsqu'ils sont correctement conçus. Les systèmes sur-mesure incorporent des caractéristiques de protection contre les explosions incluant la décharge d'explosion avec évents, la suppression chimique, la mise à la terre et la conformité aux normes NFPA les plus récentes.

Investissez dans l'excellence du transport pneumatique sur-mesure

Les convoyeurs pneumatiques sur-mesure représentent un investissement stratégique dans l'efficacité opérationnelle, la sécurité et la croissance.

Adaptés à vos matériaux spécifiques, votre aménagement et vos objectifs de production, ces systèmes offrent :

- Amélioration du flux de processus et de l'efficacité énergétique

- Contrôle amélioré de la poussière et sécurité des travailleurs

- Pleine conformité aux normes NFPA

- Conception à l'épreuve du temps supportant l'expansion de l'installation

Ne vous contentez pas de solutions standards qui compromettent votre opération.

Des questions?

Contactez Capt-Air dès maintenant pour découvrir comment un système de convoyage pneumatique sur mesure peut optimiser votre processus de manutention.